Isilinda esinomoya othambile I-Swing Check Valve

Iyini ivalvu yokuhlola i-swing yensimbi ephonswe nge-cylinder enomoya ocijile?

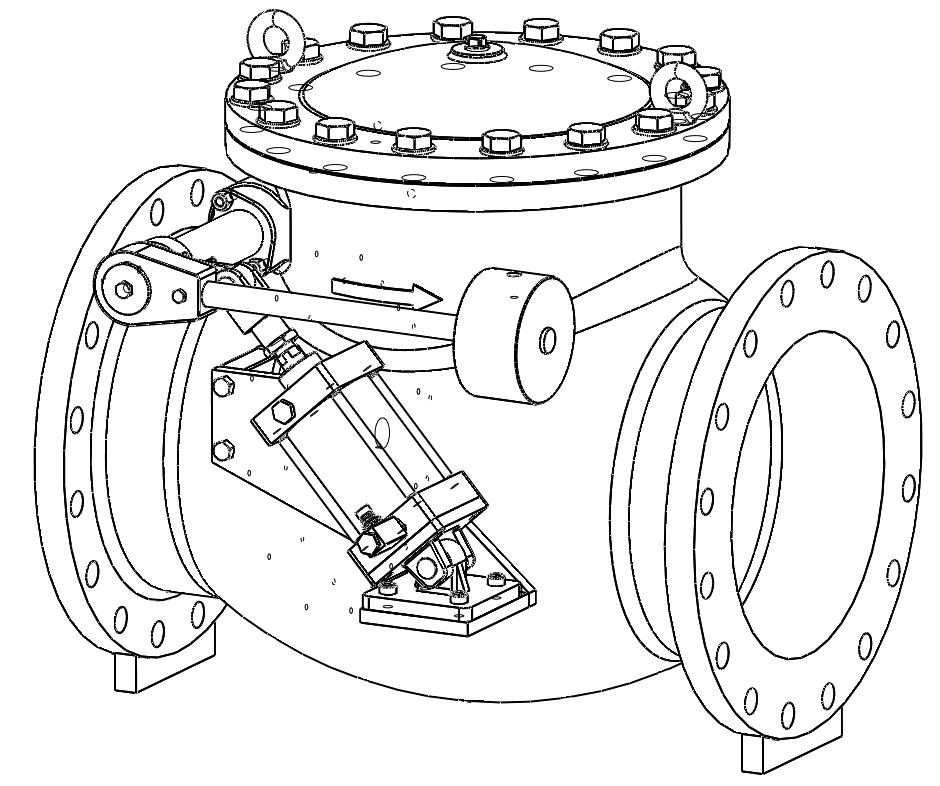

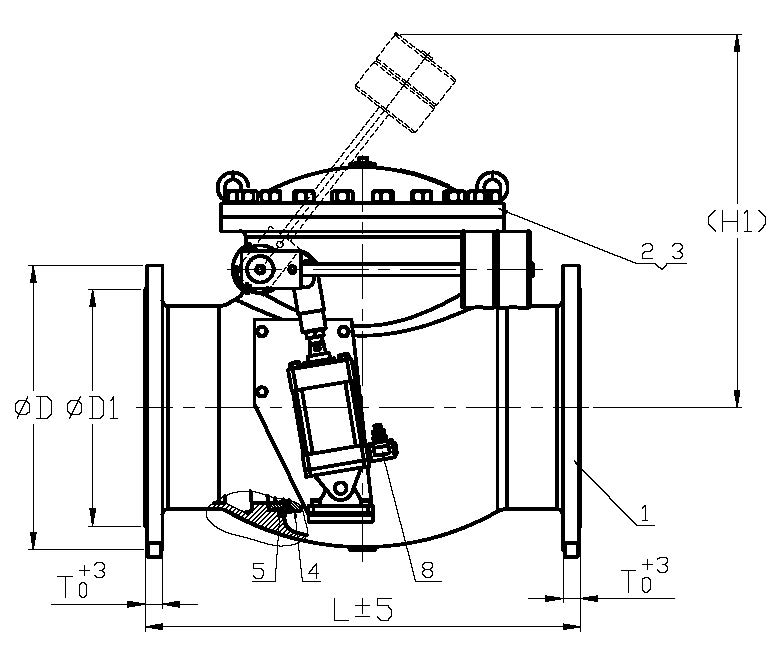

Isilinda esinomoya ocijile I-Cast Iron Swing Check Valveuhlobo lwe-swing check valve olufakwe isilinda somcamelo womoya ukuvimbela ukushayeka kanye ne-water hammer.itIqukethe umzimba wevalvu, ibhonethi, kanye nediski exhunywe ku-hinge. Idiski iyasuka esihlalweni sevalvu ukuze ivumele ukugeleza phambili, bese ibuyela esihlalweni sevalvu lapho ukugeleza okuphezulu kumisiwe, ukuvimbela ukugeleza emuva. Ivumela ukugeleza okugcwele, okungavinjelwe futhi ivala ngokuzenzakalelayo njengoba ingcindezi yehla. Lawa mavalvu avalwa ngokuphelele lapho ukugeleza kufinyelela ku-zero futhi avimbele ukugeleza emuva. Ukuxokozela kanye nokwehla kwengcindezi ngaphakathi kwevalvu kuphansi kakhulu. Ivalvu ivulwa ukugeleza koketshezi ohlangothini olulodwa bese ivala ngokuzenzakalelayo ukuvimbela ukugeleza emuva.

tI-valve yenziwe ngensimbi ephothiwe, insimbi ethambile, isetshenziselwa kakhulu ukuphakelwa kwamanzi kanye nohlelo lokukhipha amanzi, kanye neminye imikhakha yezimboni yepayipi lokukhipha amanzi ukuvimbela i-countercurrent ephakathi nendawo ekucindezelweni okuphansi kanye nokushisa okuvamile.Ingafakwa ngamadivayisi okulawula ukuvala afaka phakathi i-Air Cushioned Cylinder, i-Oil Controlled Cylinder, i-Bottom Mounted Buffer, i-Lever & Spring kanye ne-Lever & Weight.

Izici eziyinhloko ze-valve yokuhlola i-swing yensimbi ecijile enomoya

Izici kanye nezinzuzo zeI-Cast Iron Swing Check Valve

- * Ukusebenza okungenazinkinga kanye nokugcinwa okulula

- *Indawo yokugeleza kwebhore egcwele, ukumelana okuphansi kokugeleza.

- *Vimbela ukugeleza kwamanzi okuphakathi nendawo futhi ususe isando samanzi esibhubhisayo lapho ivalvu ivala. Vikela uhlelo lwamapayipi.

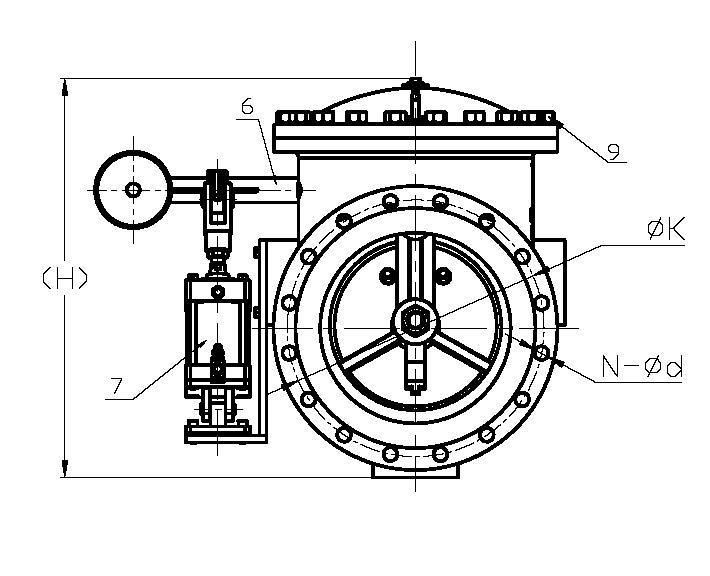

- *Ifakwe isilinda somcamelo kanye nesisindo se-lever, ixhunywe nediski ngomshafu ofanayo. Isikhathi noma isivinini sokuvula nokuvala kungalungiswa ngokulawula i-valve kanye nesisindo sesilayidi.

- *Ukusebenza kokuvala kuzinzile, kuthembekile futhi kuyamelana nokuguguleka. Isikhathi eside sokusetshenziswa, Akukho kudlidliza, Akukho msindo.

Umphathi osebenzayo we Isilinda esinomoya othambileI-Cast Iron Swing Check Valve:

- 1. Uma ipayipi elingaphezulu linyusa umfutho wamanzi, idiski yevalvu izocindezelwa ivuleke.Umgodi wediski uzoshayela i-piston yesilinda kanye ne-lever bese ukhuphula isisindo.

- 2. Uma ingcindezi yamanzi ephezulu iphakeme kunengcindezi yevalvu evulekile, idiski yevalvu izocindezelwa ivuleke. I-piston yesilinda izovulwa bese ihogela. Uma ingcindezi yamanzi ephezulu ima noma ingcindezi yangemuva, idiski yevalvu izosondela ngokushesha ngesisindo sediski esiphansi, isisindo se-lever kanye nengcindezi yangemuva. I-piston yesilinda iyawa phansi bese umoya ongaphakathi kwesilinda uqala ukukhiqiza amandla okudambisa. Ukuvala okwengeziwe esihlalweni sevalvu, kwenzeka amandla amaningi okudambisa. Lapho idiski ivala ibe yindawo evulekile engu-30%, amandla okudambisa azokhushulwa kakhulu. Idiski izoqala ukuvala kancane.

- 3. Ijubane lokuvala idiski lingalungiswa yivalvu elawulayo esilinda. Ukujika ifindo levalvu elawulayo ngokwewashi kuzokwandisa amandla okudambisa isilinda futhi kwehlise ijubane lokuvala idiski; ukujika ifindo levalvu elawulayo yesilinda ngokwewashi kuzosheshisa ukuvalwa kwediski. Ukulungiswa kwe-lock nut ngokwewashi ngemva kokuqedwa kwesikhundla sokukhiya ithini ngalesi sikhathi.

Imininingwane yobuchwepheshe ye-cast iron swing check valve

Imininingwane yobuchwepheshe yeIsilinda esinomoya ocijile I-Cast Iron Swing Check Valve

| Ukuklama Nokukhiqiza | BS5153/DIN3202 F6/AWWA C508 |

| Ubuso nobuso | I-EN558-1/ANSI B 16.10 |

| Isilinganiso sokucindezela | I-PN10-16, Iklasi 125-150 |

| Ububanzi obujwayelekile | DN50-DN600,2″-24″ |

| Iziphetho ze-Flange | EN1092-1 PN6/10/16,ASME B16.1 Cl125/ASME B16.5 Cl150 |

| Ukuhlolwa Nokuhlolwa | I-API598/EN12266/ISO5208 |

| Umzimba nediski | Insimbi ephonswe phansi, insimbi ethambile |

| Isilinda somcamelo womoya | Ingxubevange ye-aluminium |

Umbukiso Womkhiqizo:

Ukusetshenziswa kwe-valve yokuhlola i-swing yensimbi ecijile enesilinda somoya:

Lolu hlobo lweI-Cast Iron Swing Check Valveisetshenziswa kabanzi emigqeni ehambisana noketshezi kanye nezinye izinto eziwuketshezi.

- *I-HVAC/ATC

- *Ukunikezwa kwamanzi nokwelashwa

- *Imboni Yokudla Neziphuzo

- *Uhlelo lwendle

- *Imboni Yama-Pulp kanye Nephepha

- *Ukuvikelwa kwemvelo kwezimboni