Insimbi Ehlanganisiwe ye-ANSI Class 150 300 600 900 1500 2500lbs A105 Umzimba we-316 Ball Rptfe Peek Nylon Seat Insert Flange Trunnion Mounted Ball Valve Ifektri yaseChina

Iyini amavalvu ebhola afakwe ku-ATEX Trunnion?

I-ATEX ivalvu yebhola efakwe ku-trunnionkusho ukuthi ibhola livinjelwe ama-bearings futhi livunyelwe ukujikeleza kuphela, iningi lomthwalo we-hydraulic lisekelwa yizithiyo zeSistimu, okuholela ekucindezelweni okuphansi kwama-bearings kanye nokukhathala kwe-shaft.

Umfutho wepayipi ushayela isihlalo esingaphezulu ebholeni elingaguquki ukuze umfutho womugqa uphoqe isihlalo esingaphezulu ebholeni okubangela ukuthi livaleke. Ukubambelela kwebhola ngomshini kumunca ukusunduzwa okuvela kumfutho womugqa, kuvimbele ukungqubuzana okweqile phakathi kwebhola nezihlalo, ngakho-ke ngisho noma ingcindezi yokusebenza isezingeni eliphelele ihlala iphansi. Lokhu kunenzuzo ikakhulukazi lapho ivalvu yebhola iqhutshwa ngoba yehlisa usayizi we-actuator ngakho-ke izindleko eziphelele zephakheji ye-actuation yevalvu. I-trunnion iyatholakala kubo bonke osayizi kanye nazo zonke izinhlobo zomfutho kodwa ikakhulukazi ingezabosayizi abakhulu kanye nezimo zomfutho ophezulu.

Izici eziyinhloko zamavalvu ebhola afakwe i-NORTECH ATEX Trunnion

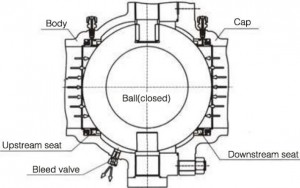

1. Ukuvimba Okubili Nokopha (DBB)

Uma ivalvu ivaliwe futhi umgodi ophakathi uthululwa ngevalvu yokukhipha amanzi, izihlalo ezingenhla nezingezansi zizovimba ngokuzimela. Omunye umsebenzi wedivayisi yokukhipha amanzi ukuthi isihlalo sevalvu singahlolwa uma kukhona ukuvuza ngesikhathi sokuhlolwa. Ngaphezu kwalokho, amadiphozithi emzimbeni angagezwa ngedivayisi yokukhipha amanzi. Idivayisi yokukhipha amanzi yakhelwe ukunciphisa umonakalo esihlalweni ngenxa yokungcola okungaphakathi.

2. I-Torque Ephansi Yokusebenza

I-valve yebhola yepayipi le-trunnion isebenzisa isakhiwo sebhola le-trunnion kanye nesihlalo se-valve esintantayo, ukuze kufezwe i-torque ephansi ngaphansi kwengcindezi yokusebenza. Isebenzisa i-PTFE ezigcobayo kanye ne-bearing yensimbi eshelelayo ukuze kuncishiswe i-friction coefficient ibe phansi kakhulu ngokuhambisana nokuqina okuphezulu kanye nesiqu sobucwebe obuphezulu.

3. Idivayisi Yokuvala Eziphuthumayo

Ama-valve ebhola anobubanzi obungaphezu noma obulingana no-6' (DN150) wonke aklanywe ngedivayisi yokufaka i-sealant esiqwini nasesihlalweni. Uma indandatho yesihlalo noma indandatho ye-stem O yonakele ngenxa yengozi, i-sealant ehambisanayo ingafakwa yidivayisi yokufaka i-sealant ukuze kugwenywe ukuvuza okuphakathi esiqwini nasesiqwini. Uma kudingeka, uhlelo lokufaka i-assistant lungasetshenziswa ukugeza nokugcoba isihlalo ukuze kugcinwe ukuhlanzeka kwaso.

Idivayisi Yokufaka Isivalo

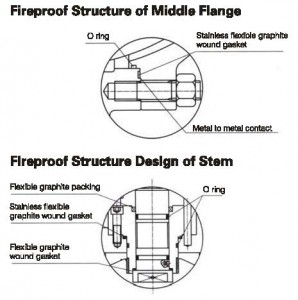

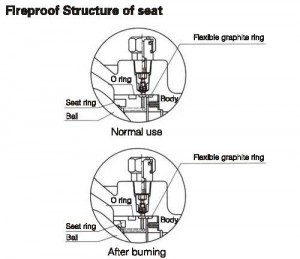

4. Umklamo Wesakhiwo Ongashi

Uma kwenzeka umlilo ngesikhathi kusetshenziswa ivalvu, indandatho yesihlalo, indandatho yesiqu se-O kanye nendandatho ye-flange ephakathi ye-O eyenziwe nge-PTFE, irabha yezinye izinto ezingezona ezensimbi izobola noma yonakale ngaphansi kokushisa okuphezulu. Ngaphansi kwengcindezi ye-medium, ivalvu yebhola izosunduza i-seat retainer ngokushesha iye ebholeni ukuze yenze indandatho yensimbi ixhumane nebhola futhi yakhe isakhiwo sokuvala insimbi esisekelayo kuya kwensimbi, esingalawula ngempumelelo ukuvuza kwevalvu. Umklamo wesakhiwo esingashisi umlilo se-trunnion pipeline ball valve uhambisana nezidingo eziku-API 607, API 6FA, BS 6755 kanye nezinye izindinganiso.

6. Isakhiwo sokuvala isihlalo esithembekile

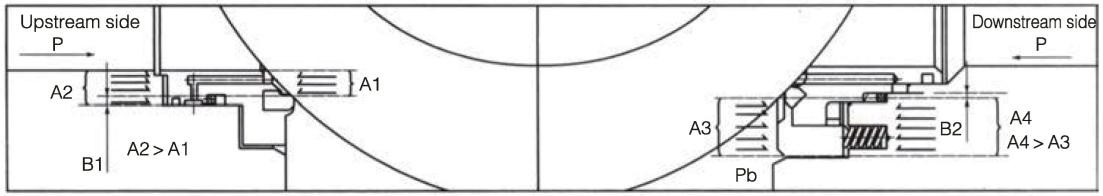

Ukuvalwa kwesihlalo kutholakala ngokusebenzisa izibambi zezihlalo ezimbili ezintantayo, Zingantanta nge-axial ukuvimba uketshezi, okuhlanganisa ukuvalwa kwebhola kanye nokuvalwa komzimba. Ukuvalwa kwesihlalo se-valve ngengcindezi ephansi kutholakala ngokuqiniswa kwentwasahlobo. Ngaphezu kwalokho, umphumela we-piston wesihlalo se-valve uklanywe kahle, okwenza ukuvalwa kwengcindezi ephezulu kutholakale ngengcindezi ye-medium uqobo. Izinhlobo ezimbili ezilandelayo zokuvalwa kwebhola zingabonakala.

7. Ukuvalwa Okukodwa

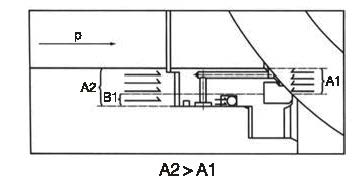

(Ukukhululeka Kokucindezela Okuzenzakalelayo Emgodini Ophakathi Wevalvu) Ngokuvamile, kusetshenziswa isakhiwo esisodwa sokuvala. Okusho ukuthi, kukhona ukuvala okuphezulu kuphela. Njengoba kusetshenziswa izihlalo zokuvala ezizimele ezithwele intwasahlobo ephezulu kanye nephansi, umgodi wevalvu ongaphakathi ocindezela kakhulu unganqoba umphumela wokuqinisa wentwasahlobo, ukuze isihlalo sikhululwe ebholeni futhi sithole ukukhululeka kokucindezela okuzenzakalelayo engxenyeni engezansi. Uhlangothi oluphezulu: Lapho isihlalo sihamba nge-axial eceleni kwevalvu, ingcindezi ethi “P” esetshenziswa engxenyeni ephezulu (i-inlet) ikhiqiza amandla angemuva ku-A1, Njengoba i-A2 iphakeme kune-A1, i-A2-A1=B1, amandla ku-B1 azosunduza isihlalo siye ebholeni futhi athole ukuvalwa okuqinile kwengxenye ephezulu.

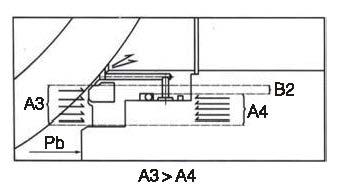

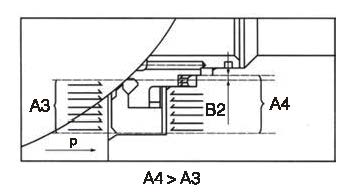

Uhlangothi olungezansi: Uma ingcindezi ethi “Pb” ngaphakathi kwe-valve Cavity ikhula, amandla asetshenziswa ku-A3 aphakeme kunalawo aku-A4. Njengoba i-A3-A4=B2, umehluko wengcindezi ku-B2 uzonqoba amandla entwasahlobo ukuze isihlalo sikhululwe ebholeni futhi kutholakale ukukhululeka kwengcindezi ye-valve engxenyeni engezansi ngemuva kwalokho, isihlalo nebhola kuzovalwa futhi ngaphansi kwesenzo sentwasahlobo.

Ukuvalwa kwesibili: Ngaphansi komfula.

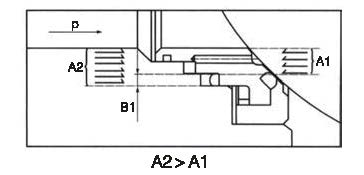

Uma umehluko wokucindezela uphansi noma kungekho umehluko wokucindezela, isihlalo esintantayo sizohamba nge-axial eceleni kwevalvu ngaphansi kwesenzo sentwasahlobo bese sisunduza isihlalo siye ebholeni ukuze sigcine ukuvala okuqinile. Lapho ukucindezela kwesikhala sevalvu u-P kukhuphuka, amandla asebenza endaweni engu-A4 yesihlalo sevalvu ephakeme kunamandla asebenza endaweni engu-A3,A4-A3=B1. Ngakho-ke, amandla aku-B1 azosunduza isihlalo siye ebholeni futhi aqinisekise ukuvalwa okuqinile kwengxenye ephezulu.

9. Idivayisi Yokusiza Ukuphepha

Njengoba ivalvu yebhola yakhelwe ngokuvalwa okuphambili nokwesibili okuthuthukisiwe okunomphumela wepiston ephindwe kabili, futhi umgodi ophakathi awukwazi ukukhulula ingcindezi ngokuzenzakalelayo, ivalvu yokukhulula ukuphepha kumele ifakwe emzimbeni ukuze kuvinjelwe ingozi yokulimala ngokweqile ngaphakathi komgodi wevalvu okungenzeka ngenxa yokwanda kokushisa kwe-medium. Ukuxhumeka kwevalvu yokukhulula ukuphepha ngokuvamile kuyi-NPT 1/2. Elinye iphuzu okufanele liqashelwe ukuthi umgodi wevalvu yokukhulula ukuphepha ukhishwa ngqo emoyeni. Uma ukukhishwa ngqo emoyeni kungavunyelwe, siphakamisa ukuthi ivalvu yebhola enesakhiwo esikhethekile sokukhulula ingcindezi ngokuzenzakalelayo iye emfuleni ongaphezulu kufanele isetshenziswe. Bheka okulandelayo ukuze uthole imininingwane. Sicela ukubonise ngokulandelana uma ungayidingi ivalvu yokukhulula ukuphepha noma uma ungathanda ukusebenzisa ivalvu yebhola enesakhiwo esikhethekile sokukhulula ingcindezi ngokuzenzakalelayo iye emfuleni ongaphezulu.

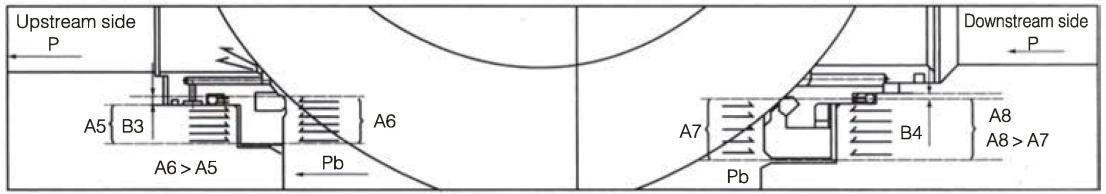

10. Isakhiwo Esikhethekile Sokukhululeka Kokucindezela Okuzenzakalelayo Kubheke Ekusakazeni Okuphezulu

Njengoba ivalvu yebhola yakhelwe ngokuvalwa okuphambili nokwesibili okuthuthukisiwe okunomphumela wepiston ephindwe kabili, futhi umgodi ophakathi awukwazi ukukhulula ingcindezi ngokuzenzakalelayo, ivalvu yebhola nesakhiwo esikhethekile kuyanconywa ukuhlangabezana nezidingo zokukhululeka kwengcindezi ngokuzenzakalelayo nokuqinisekisa ukuthi akukho ukungcoliswa kwemvelo. Esakhiweni, umfudlana ongaphezulu usebenzisa ukuvalwa okuyinhloko kanti umfudlana ongezansi usebenzisa ukuvalwa okuyinhloko nokwesibili. Lapho ivalvu yebhola ivaliwe, ingcindezi engaphakathi kwevalvu ingakhulula ingcindezi ngokuzenzakalelayo emfudlaneni ongaphezulu, ukuze kugwenywe ingozi ebangelwa ingcindezi yomgodi. Lapho isihlalo esiyinhloko sonakele futhi sivuza, isihlalo sesibili singadlala nomsebenzi wokuvala. Kodwa kufanele kunakwe ngokukhethekile indlela yokugeleza kwevalvu yebhola. Ngesikhathi sokufakwa. Qaphela iziqondiso ezingenhla nezingezansi. Bheka imidwebo elandelayo yesimiso sokuvala sevalvu nesakhiwo esikhethekile.

Umdwebo oyinhloko we-ball valve yokuvala phezulu naphansi komfula

Umdwebo oyisisekelo wokukhululeka kwengcindezi ye-ball valve cavity ukuya ekufakweni komfudlana ongaphezulu kanye nokuvalwa komfudlana ophansi

11. Isiqu Sobufakazi Bokuqhuma

Isiqu samukela isakhiwo esingavumeli ukuqhunyiswa. Isiqu sakhiwe ngesinyathelo sonyawo phansi ukuze ngokubeka isembozo sangaphezulu kanye nesikulufu, isiqu singaphumi yi-medium ngisho noma kwenzeka ukwenyuka kwengcindezi okungavamile emgodini we-valve.

Isiqu Esivikela Ukuqhuma

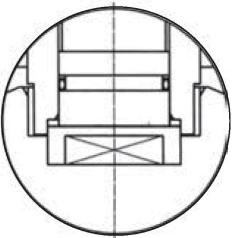

13. Isiqu Sokwelulwa

Ngokuphathelene nevalvu ehlanganisiwe, isiqu sokwelula singanikezwa uma kudingeka ukusebenza komhlabathi. Isiqu sokwelula sakhiwe ngesiqu, ivalvu yokujova ye-sealant, kanye nevalvu yokukhipha amanzi enganwetshwa iye phezulu ukuze kube lula ukusebenza. Abasebenzisi kufanele babonise izidingo zesiqu sokwelula kanye nobude lapho bebeka ama-oda. Kuvalvu yebhola eqhutshwa nge-actuators kagesi, yomoya kanye neyomoya - ye-hydraulic, ubude besiqu sokwelula kufanele busuke enkabeni yepayipi kuya ku-flange ephezulu.

Umdwebo wesimiso wesiqu sokwelulwa

Imininingwane yamavalvu ebhola afakwe ku-NORTECH ATEX Trunnion

Imininingwane Yobuchwepheshe be-Trunnion Ball Valve

| Ububanzi obujwayelekile | 2”-56”(DN50-DN1400) |

| Uhlobo Lokuxhumeka | I-RF/BW/RTJ |

| Izinga lokuklama | I-API 6D/ASME B16.34/API608/MSS SP-72 ivalvu yebhola |

| Izinto zomzimba | Insimbi ehlanganisiwe/Insimbi engagqwali/Insimbi engagqwali/Insimbi engagqwali eyenziwe |

| Izinto zebhola | A105+ENP/F304/F316/F304L/F316L |

| Izinto zesihlalo | I-PTFE/PPL/INAYLON/UKUBHEKA |

| Izinga lokushisa lokusebenza | Kufika ku-120°C kwe-PTFE |

|

| Kufika ku-250°C ukuze uthole i-PPL/PEEK |

|

| Kufika ku-80°C ye-NYLON |

| Isiphetho se-Flange | I-ASME B16.5 RF/RTJ |

| Ukuphela kwe-BW | I-ASME B 16.25 |

| Ubuso nobuso | I-ASME B 16.10 |

| Izinga lokushisa lokucindezela | I-ASME B 16.34 |

| Iphephile emlilweni futhi ayishintshi | I-API 607/API 6FA |

| Izinga lokuhlola | I-API598/EN12266/ISO5208 |

| Ubufakazi bokubukiswa | I-ATEX |

| Uhlobo lokusebenza | Ibhokisi legiya elenziwa ngesandla/i-actuator ye-pneumatic/i-actuator kagesi |

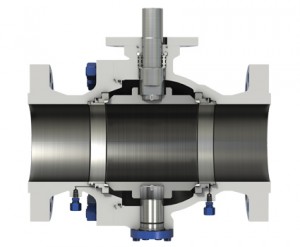

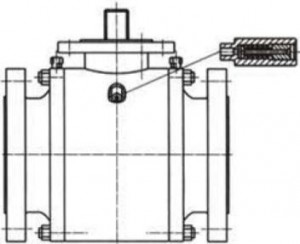

Umbukiso Womkhiqizo:

Ukusetshenziswa kwamavalvu ebhola afakwe i-NORTECH ATEX Trunnion

Lolu hlobo lweI-ATEX I-Trunnion Egibele Ibhola Valveisetshenziswa kabanzi ohlelweni lokusebenzisa, ukucwenga kanye nokuthutha uwoyela, igesi kanye namaminerali. Ingasetshenziswa futhi ukukhiqiza imikhiqizo yamakhemikhali, imithi; uhlelo lokukhiqiza ugesi wamanzi, amandla okushisa kanye namandla enuzi; uhlelo lokukhipha amanzi,